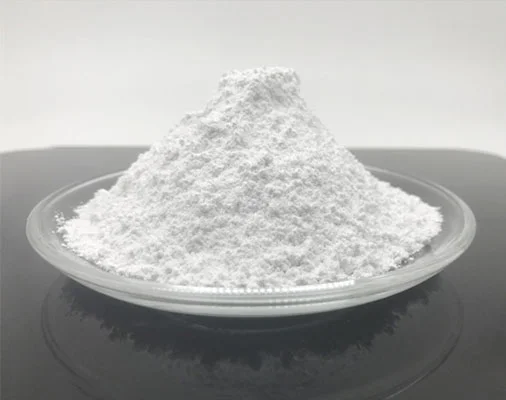

Protocatechuic acid (PCA), a naturally occurring phenolic compound found in various plants, fruits, and vegetables, has emerged as a significant focal point in the pharmaceutical, cosmetic, and food industries, thanks to its robust antioxidant and anti-inflammatory properties. Despite its recognized potential, the commercial production of high-purity PCA poses a formidable challenge due to the intricate nature of its biosynthesis process. This blog post by Viablife aims to unravel the complexities involved in the production of high-purity protocatechuic acid, exploring the diverse pathways, enzymes, and influential factors that shape its synthesis. By delving into this nuanced process, researchers and industries can optimize production methods, ushering in novel applications and improved accessibility of this valuable compound.

1. Overview of Protocatechuic Acid (PCA):

Protocatechuic acid, also known as 3,4-dihydroxybenzoic acid, belongs to the class of hydroxybenzoic acids and is widely distributed in nature. Its presence in various sources such as green tea, coffee, fruits, and vegetables has garnered attention for its potential health benefits, encompassing antioxidant, anti-inflammatory, antimicrobial, and anticancer properties.

2. Biosynthesis Pathways of Protocatechuic Acid:

The biosynthesis of protocatechuic acid unfolds through intricate pathways, influenced by plant species and environmental conditions. Two primary routes, the shikimate pathway and the phenylpropanoid pathway, govern this complex synthesis.

2.1 Shikimate Pathway:

Initiating with the condensation of phosphoenolpyruvate (PEP) and erythrose-4-phosphate (E4P), the shikimate pathway traverses enzymatic reactions, culminating in the formation of chorismate. This compound undergoes further transformation into protocatechuic acid, orchestrated by key enzymes including chorismate mutase, prephenate dehydrogenase, and protocatechuate decarboxylase.

2.2 Phenylpropanoid Pathway:

Originating from phenylalanine, derived from the shikimate pathway, the phenylpropanoid pathway orchestrates the conversion of cinnamic acid to protocatechuic acid. This transformation involves enzymes such as phenylalanine ammonia-lyase (PAL), cinnamate 4-hydroxylase (C4H), 4-coumarate:CoA ligase (4CL), and caffeic acid O-methyltransferase (COMT).

3. Factors Influencing Protocatechuic Acid Biosynthesis:

Several factors intricately mold the biosynthesis of protocatechuic acid, impacting both quantity and quality. Genetic factors, environmental conditions, and elicitors play pivotal roles in this process.

3.1 Genetic Factors:

The genetic makeup of plants dictates their ability to produce protocatechuic acid. Genetic engineering techniques can amplify the expression of key enzymes, augmenting protocatechuic acid production. Manipulating transcription factors further influences the biosynthesis process.

3.2 Environmental Conditions:

Light, temperature, humidity, and nutrient availability significantly affect protocatechuic acid biosynthesis. Maintaining optimal conditions is imperative for maximizing production, with studies highlighting the role of UV-B radiation in inducing protocatechuic acid production in specific plant species.

3.3 Elicitors:

Natural or synthetic substances known as elicitors stimulate secondary metabolite production, including protocatechuic acid. Elicitors such as salicylic acid, methyl jasmonate, and chitosan trigger defense mechanisms in plants, enhancing protocatechuic acid production.

4. Optimization Strategies for High-Purity Protocatechuic Acid Production:

Achieving high-purity protocatechuic acid necessitates strategic optimization throughout the biosynthesis process. Metabolic engineering, bioprocess optimization, and downstream purification techniques play pivotal roles in this endeavor.

4.1 Metabolic Engineering:

Manipulating metabolic pathways through genetic interventions enhances protocatechuic acid production. Overexpressing key enzymes and suppressing competing pathways can increase the flux towards protocatechuic acid.

4.2 Bioprocess Optimization:

Focusing on fermentation conditions, bioprocess optimization involves fine-tuning parameters such as pH, temperature, oxygen supply, and nutrient availability. Employing bioreactors and advanced fermentation techniques enhances production efficiency.

4.3 Downstream Purification Techniques:

Attaining high-purity protocatechuic acid demands efficient purification techniques. Solvent extraction, chromatography, crystallization, and membrane filtration are key methods, each with distinct advantages and limitations. A combination of techniques ensures the desired purity level.

Conclusion:

The intricate biosynthesis of high-purity protocatechuic acid involves multifaceted pathways, enzymes, and influencing factors. Understanding these complexities is paramount for optimizing production methods and enhancing accessibility to this valuable compound. Genetic engineering, environmental optimization, and elicitor application can amplify protocatechuic acid production, while downstream purification techniques guarantee high purity. With ongoing research and technological advancements, large-scale commercial production of high-purity protocatechuic acid becomes a tangible reality, unlocking its potential across diverse industries. Harnessing the power of this natural compound paves the way for innovative applications in medicine, cosmetics, and functional foods, contributing to a healthier and more sustainable future.

Related Products:

2.Tyrosol

Leave a Message

Leave a Message